When car parts get beyond circulation as second hand spares, they have to be recycled. Around 80% of a car can be turned into usable products, making car recycling big business today. There are now whole companies that exist around taking different materials from scrapped cars and turning them into reusable products. What are these materials and how are they reprocessed?

Steel

As most of a car’s bodywork is made from steel, recovering this from cars is an essential process for the automotive industry. Recycled steel only uses around 25% of the energy of newly machined steel in its manufacture, making recycled steel a truly green and environmentally friendly choice. Old cars are stripped of all usable parts, such as the batteries, seats and tyres, and fed into a crushing unit. This transforms the old car into a single block that can then be sold to a reprocessing plant. Here the block is broken into its constituent elements and smelted down, allowing the steel to be collected and pressed into shape for reuse.

Rubber Tyres

The rubber from old car tyres can be broken down in a number of ways. They can undergo pyrolysis, where the rubber is converted into a kind of fuel vapour, they can be used as fuel in coal manufacturing plants, or may find their way into use in construction as collision prevention devices such as bumpers on moorings. Finally they can also be turned into a kind of rubber crumb that is used in the manufacture of safety matting for children’s playgrounds.

Car Batteries

Car batteries must be recycled. Believe it or not, they actually go back to a processing plant where they are made into new batteries. These industrial centres feature units that crush the old batteries down into their component parts and then use a system of washes and different techniques to separate out the various materials. The plastic can be sold to other recycling plants, the acid is sent through to waste chemical processing units where it can be mixed with other reagents to form useful compounds, and the lead is made into new batteries.

Glass and Upholstery

The glass in your car can be recycled in the same way as the glass in bottles and jars that are thrown into your local recycling bins. Here the glass is crushed down into small granules before being melted. This allows the old glass to be used in new glass products ranging from food containers through to windows. Whilst car upholstery cannot be traditionally recycled, there are a number of green companies that are quite literally recovering old car upholstery such as seating, and making it into new home furniture.

Oil

Car oil does not mix with impurities, they merely stay suspended within the fluid. This means that oil can be cleaned and filtered at a reprocessing plant and put back into use. This is done via a process that first dehydrates the oil to remove water and anti-freeze, then distils the oil before it finally undergoes heat-treatment. The recycled oil finds its way back into normal circulation, and the chances are that some of the oil you are using in your current vehicle has been recovered in this way.

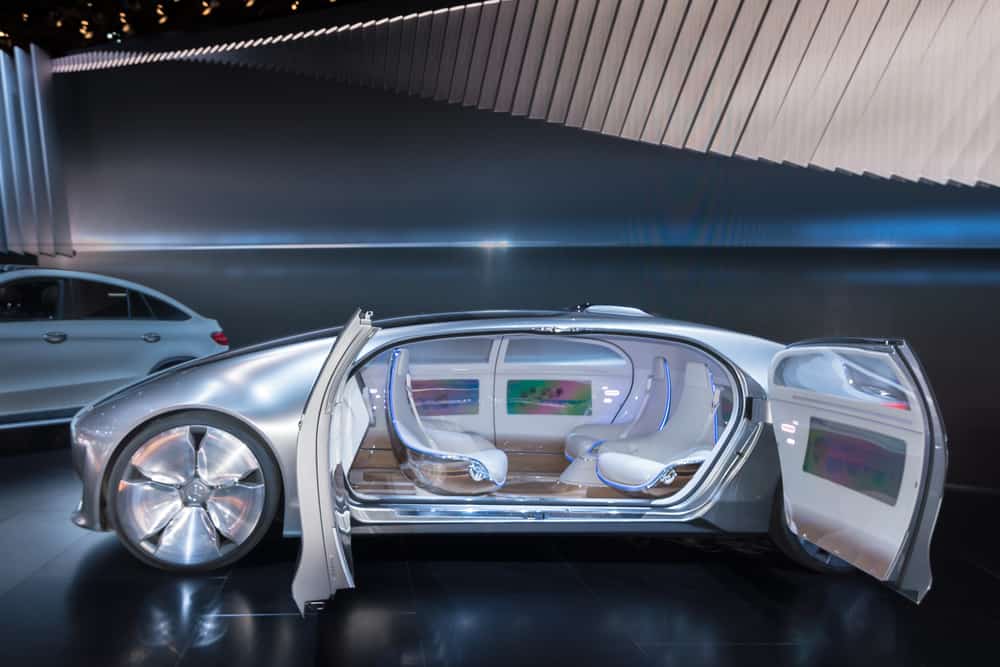

The Future

As we move towards an uncertain future, resources are becoming more limited and as a species we have to look at the way we treat our planet. With increasing amounts of products featuring recyclable elements it is possible that we will see cars in the future that last forever. By this we mean that the competitive production of vehicles may stop and everyone will own the same kind of car, which will be designed so that when any of its parts fail they can simply be replaced as opposed to purchasing a new vehicle every few years.

.png)