There are many tell-tale signs that your car’s clutch is on its way out. The clutch may feel spongy during operation, requiring you to let it out more than normal whilst you change gear. A burning smell also can indicate that there is excess friction caused by a slipping clutch or you may simply have experienced a huge amount of difficulty in changing gear. Whatever the reason behind your failing clutch, you can change this part yourself with a sufficient amount of mechanical knowledge and the right tools. This step by step guide goes through the basic fundamentals of performing this procedure

1. First Steps

As with all mechanical work on your car, you will need to park your vehicle in a place where you can work safely on a flat, stable surface. In the first instance you will need to jack up the front end and also stabilise the engine with jack below the oil pan. Then take off an engine mount, which will then allow you to remove the transmission.

2. Removal of the Clutch

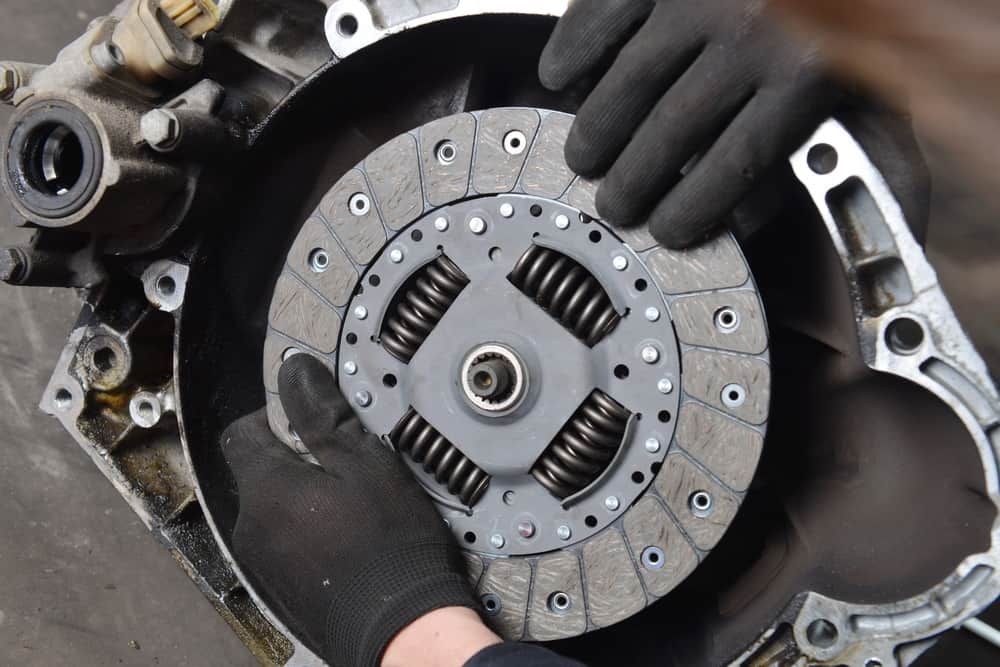

Next you will need to separate the engine from the transmission. This is held in place by bolts around the flywheel housing, which will need to be removed. When this is complete carefully push the transmission away from the engine, watching to ensure the input shift clears the pressure plate. Following this, remove the bolts around the pressure plate and take it and the clutch plate out.

3. Clean and Check

Before you go ahead and install the replacement clutch you may wish to check that the flywheel is in good working order, inspecting the surface for any scoring or hot spots. Also ensure that the transmission’s input shaft isn’t leaking or that the flywheel’s seals need replacement. It is also advisable that you clean the crankshaft flange before returning the flywheel to position.

4. Install the New Clutch

First put in the clutch disc and pressure plate. It is then necessary to attach the new release to the release fork before putting in the transmission. Then hoist the transmission into position and gently move it forward until the input shaft glides into the clutch disc’s spindled hole. Replace the bolts and mounts that you initially removed in step one of the process, ensuring that each is fully tightened.

5. Cables and Action

Whilst you are replacing your car’s clutch you may also wish to replace the operating cable to ensure that this is in good working order. If you do not change out this part we would recommend that you adjust it to allow for the right amount of play. Also check that your clutch’s self-adjusting action is working correctly by depressing the slave cylinder fully into the bore. You shouldn’t need to worry about the clutch master cylinder during this stage.

Finally you will want to take the car out for a test drive to ensure that the car’s new clutch is working correctly. We would always advise you do this on a local road where there is not much traffic in case there is a problem when changing gear.

.png)